規格/ CAD

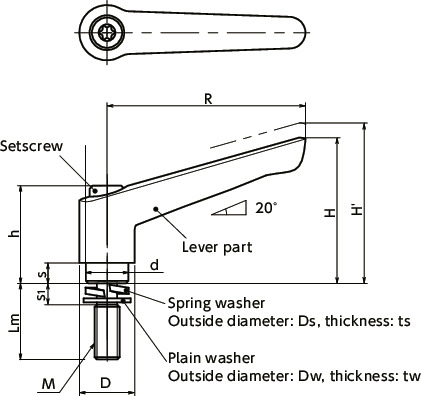

單位:毫米

| 零件號 | M(粗) 標稱螺紋 |

瀝青 | LM | [R | H | H' | H | 小號 | ð | ð | Ds | TS | w | tw | S1 | B * 1 | 牙齒號 | 最高加載 | 最高夾緊力 | 塊 (G) |

身體 顏色 |

電腦輔助設計 下載 |

大車 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LEM-10-16-W-BK | M10 | 1.5 | 16 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 69 | BK | CAD | RFQ |

| LEM-10-16-W-OR | M10 | 1.5 | 16 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 69 | 要么 | CAD | RFQ |

| LEM-10-16-W-SG | M10 | 1.5 | 16 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 69 | SG | CAD | RFQ |

| LEM-10-20-W-BK | M10 | 1.5 | 20 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 71 | BK | CAD | RFQ |

| LEM-10-20-W-OR | M10 | 1.5 | 20 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 71 | 要么 | CAD | RFQ |

| LEM-10-20-W-SG | M10 | 1.5 | 20 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 71 | SG | CAD | RFQ |

| LEM-10-25-W-BK | M10 | 1.5 | 25 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 74 | BK | CAD | RFQ |

| LEM-10-25-W-OR | M10 | 1.5 | 25 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 74 | 要么 | CAD | RFQ |

| LEM-10-25-W-SG | M10 | 1.5 | 25 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 74 | SG | CAD | RFQ |

| LEM-10-32-W-BK | M10 | 1.5 | 32 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 77 | BK | CAD | RFQ |

| LEM-10-32-W-OR | M10 | 1.5 | 32 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 77 | 要么 | CAD | RFQ |

| LEM-10-32-W-SG | M10 | 1.5 | 32 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 77 | SG | CAD | RFQ |

| LEM-10-40-W-BK | M10 | 1.5 | 40 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 81 | BK | CAD | RFQ |

| LEM-10-40-W-OR | M10 | 1.5 | 40 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 81 | 要么 | CAD | RFQ |

| LEM-10-40-W-SG | M10 | 1.5 | 40 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 81 | SG | CAD | RFQ |

| LEM-10-50-W-BK | M10 | 1.5 | 50 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 86 | BK | CAD | RFQ |

| LEM-10-50-W-OR | M10 | 1.5 | 50 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 86 | 要么 | CAD | RFQ |

| LEM-10-50-W-SG | M10 | 1.5 | 50 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 86 | SG | CAD | RFQ |

| LEM-10-63-W-BK | M10 | 1.5 | 63 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 92 | BK | CAD | RFQ |

| LEM-10-63-W-OR | M10 | 1.5 | 63 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 92 | 要么 | CAD | RFQ |

| LEM-10-63-W-SG | M10 | 1.5 | 63 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 92 | SG | CAD | RFQ |

| LEM-10-80-W-BK | M10 | 1.5 | 80 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 101 | BK | CAD | RFQ |

| LEM-10-80-W-OR | M10 | 1.5 | 80 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 101 | 要么 | CAD | RFQ |

| LEM-10-80-W-SG | M10 | 1.5 | 80 | 78 | 55.4 | 59.4 | 36 | 8 | 21 | 16 | 18.4 | 2.5 | 20 | 1 | 7 | 11 | 26 | 200 | 11 | 101 | SG | CAD | RFQ |

材料/表面處理

| LEM-W | |

|---|---|

| 槓桿部分 | 尼龍6(各種顏色) |

| 螺紋部分 | SUM22L 鐵氧體氧化膜(黑色) |

| 緊定螺釘 | 鋼 鐵氧體氧化膜(黑色) |

| 鋸齒環(插入) | 鋅壓鑄 |

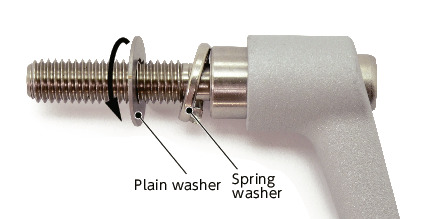

| 春天洗衣機 | SUS304 |

| 平原洗衣機 | SUS304 |

| 彈簧 | 不銹鋼絲 |

特點

- 帶彈簧墊圈的塑料夾緊桿。

- 這樣就無需安裝彈簧墊圈。

- 普通墊圈的特殊形狀可固定彈簧墊圈。

- 平墊圈可以沿著螺紋脊旋轉並卸下。彈簧墊圈可以替換為其他墊圈組件。

- 鋅壓鑄鋸齒環插入到塑料槓桿主體中。它可以與金屬螺釘的鋸齒達到足夠的裝配強度。

- 該手柄有3種顏色可供選擇。可以通過零件號的結尾符號選擇它們。

| 結束符號 | 槓桿零件顏色 |

|---|---|

| BK | 亞光黑 |

| SG | 啞光銀 |

| 要么 | 啞光橙 |

只需一分鐘就能理解!如何使用夾緊桿。

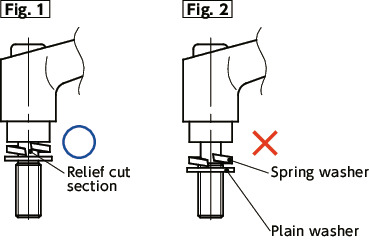

使用注意事項

擰緊槓桿之前,請確保平墊圈位於如圖1所示的凸紋切口部分。 如圖2所示,在鉤住螺紋時擰緊平墊圈可能會導致平墊圈變形。

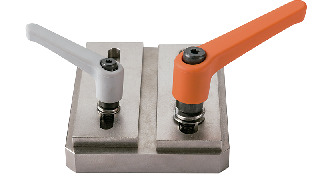

用法示例

可用於擰緊長孔。

開槽孔寬度的公稱螺紋應為+0.5 mm或更小。